How to Prevent Discrepancies and Questions Around the Reliability of Certificates of Analysis (CoAs)

- Warning letter to Juno Therapeutics, lnc. October 16, 2020

- Warning Letter to Cellex-C International, August 2, 2017

- Warning Letter to Kim Chemicals Private Ltd, October 16, 2017

- Warning Letter to Lumis Pharmaceuticals, March 2, 2017

- Warning Letter to Su Zhou Pharmaceuticals, January 16, 2017

- Warning Letter to Sal Pharmaceuticals, April 20, 2017

- Preventing the Discrepancies

- The process for preparing the requirements for the CoA, processing receipt of CoA's, and maintaining control

- What is the right approach is managing and evaluating CoAs?

- What key information should the CoAs consist of

- How to verify the information instead of taking vendor data at face value

- How to develop a systematic approach to CoAs and vendor data management

- Quality oversight of Contract Manufacturing Organizations (CMOs)

- How to identify false CoAs

- Guidance: EN ISO/IEC 17025:2005 and FDA's Q7A Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients

- a title

- The name and address of the laboratory, and the location where the tests were performed, if different from the address of the laboratory

- the name and address of the customer

- identification of the method used

- a description of, the condition of, and unambiguous identification of the item(s) tested

- the date of receipt of the test item(s) where this is critical to the validity and application of the results, and the date(s) of performance of the test

- reference to the sampling plan and procedures used by the laboratory or other bodies where these are relevant to the validity or application of the results

- the test results with, where appropriate, the units of measurement

- where applicable, a statement on the estimated uncertainty of measurement

- where appropriate, a statement of compliance/non-compliance with requirements and/or specifications

- where appropriate and needed, opinions and interpretations.

- the name(s), function(s) and signature(s) or equivalent identification of person(s) authorizing the test report certificate;

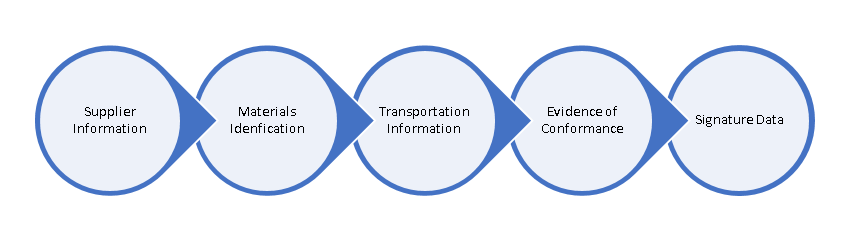

- Overview of a CoA

One of the frequently cited FDA observations includes discrepancies and questions around the reliability of certificates of analysis.

CoAs are documents provided by suppliers of APIs, excipients, and other materials to their customers, the drug product manufactures. These documents are important and tangible evidence of the manufacturer's relationship with suppliers. They play a key role at the point where the materials, laboratory control systems, and manufacturing interconnect. CoAs are highly critical to data integrity compliance.

How can you prevent such a discrepancy? What guidance is available? and what training can help? This article provides the answers.

Following are some examples of such FDA warning letters about CoAs:

To mitigate the risk of non-compliance, manufacturers and suppliers must understand:

By gaining knowledge of the industry guidance about CoAs, you can not only learn its requirements but will understand how to deal with a related problem should it occur.

The following guidance documents can help you get the fundamentals of the concepts down

The EN ISO/IEC 17025:2005 standard is a go-to reference guide for the issue of a CoA. The CoA should include:

The Q7A Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients (11.4) provides the following requirements:

"Authentic certificates of analysis should be issued for each batch of intermediate or API on request.

Information on the name of the intermediate or API including, where appropriate, its grade, the batch number, and the date of release should be provided on the certificate of analysis. For intermediates or APIs with an expiry date, the expiry date should be provided on the label and certificate of analysis. For intermediates or APIs with a retest date, the retest date should be indicated on the label and/or certificate of analysis.

The certificate should list each test performed in accordance with compendial or customer requirements, including the acceptance limits, and the numerical results obtained (if test results are numerical).

Certificates should be dated and signed by authorized personnel of the quality unit(s) and should show the name, address, and telephone number of the original manufacturer. Where the analysis has been carried out by a repacker or reprocessor, the certificate of analysis should show the name, address, and telephone number of the repacker/reprocessor and reference the name of the original manufacturer.

If new certificates are issued by or on behalf of repackers/reprocessors, agents or brokers, these certificates should show the name, address and telephone number of the laboratory that performed the analysis. They should also contain a reference to the name and address of the original manufacturer and to the original batch certificate, a copy of which should be attached."

Looking for related training? Check out our Seminars and Webinars for FDA-regulated Companies.