Is Your Team Following Good Manufacturing Practices?

By: Priyabrata Sahoo, Associate Vice President, ComplianceOnline.

If you work at a regulated company and your job responsibilities require you to ensure that your team has a comprehensive understanding of the basic concepts of Good Manufacturing Practices (GMP), this article will help. Regulatory agencies require companies who develop, manufacture, package and/or distribute Pharmaceuticals, Dietary supplements, Biologics, Medical Devices and/or combination products to ensure their professionals who understand and practice GMP.

Help them become brilliant on the basics

Your job and your team's job involve GMP. Gaining knowledge about GMP will help you integrate its best practices into your daily work habits. It will maximize the quality of performance and the product you are involved in manufacturing. A minor investment in learning GMP, especially Quality Unit Management, is an excellent assurance to avoid regulatory action that can have a damaging market impact on you, the company and potentially enormous cost for remediation.

What is GMP?

Good Manufacturing Practice (GMP) is a system for ensuring that products are consistently manufactured and controlled in harmony with the quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product.' - WHO

What are the basic principles of GMP?

The 10 basic principles of GMP should govern the day-to-day operations of a Company. You do well to bear these principles in mind when making decisions that have GMP implications.

| Principle #1 Written Procedures |

Make sure you have step-by-step written procedures that provide a roadmap for consistency in performance. |

| Principle #2 Compliance with procedures |

Follow the procedures closely to ensure consistency in product quality. |

| Principle #3 Documentation |

Document your work promptly and accurately in chronological order to ensure compliance and trace any issues if there is ever a complaint regarding the product. |

| Principle #4 Validation |

Validate all systems and processes to ensure that quality and consistency are fulfilled according to the plan. |

| Principle #5 Facility and Equipment |

As per this principle, the productivity, product quality and safety must be integrated into the design and construction of the Company's facilities and equipment. |

| Principle #6 Maintenance |

Regularly maintain equipment and facilities to minimize safety issues of contamination and quality control. Maintain written records of the work performed. |

| Principle #7 Job Competency |

Demonstrate job confidence in your role. Ensure you have clearly defined and developed job competencies required for specific roles. |

| Principle #8 Contamination control |

Practice good hygiene to protect the product from contamination. Make it part of your daily routine. Ensure you have documented standards guidelines to follow so that you do not deviate from the degree of cleanliness required for the product. |

| Principle #9 Quality control |

As per this principle, quality should be directly built into the product through methodical control of components and processes. Ensure that quality control measures are in place in the area you work whether manufacturing, packaging, labeling, distribution, and marketing. |

| Principle #10 Audits |

To make sure how well the GMP is implemented, Audits at regular frequency must be in place according to this principle. |

How is GMP ensured in organizations?

Organizations typically ensure GMP through the effective use of a Quality Management System (QMS).

- 'A QMS is a collection of business processes focused on achieving quality policy and quality objectives to meet customer requirements. The technique is used in a wide range of businesses, including those who manufacture medical devices.

- A QMS controls three managerial processes: quality planning, quality control and quality improvement.' - FDA

What are the different GMP Guideline Versions?

The following provides links to many versions of the GMP. However, it is not a comprehensive list.

Facts about Current Good Manufacturing Practices (CGMPs)" - The phrase "current good manufacturing practices" (CGMP)' is used to describe the GMP regulations.

"Current Good Manufacturing Practices"

"Quality System (QS) Regulation / Medical Device Good Manufacturing Practices"

"Draft Guidance for Industry: Cosmetic Good Manufacturing Practices"

"The World Health Organization (WHO) GMP'"

(EU-GMP) enforces similar requirements to WHO GMP

How do the Regulatory Agencies determine if a Company follows GMP?

Regulatory agencies inspect manufacturing facilities worldwide. Highly trained staff from the regulatory agencies perform the inspections using a standard approach.

How should you prepare for GMP Inspection or Audit?

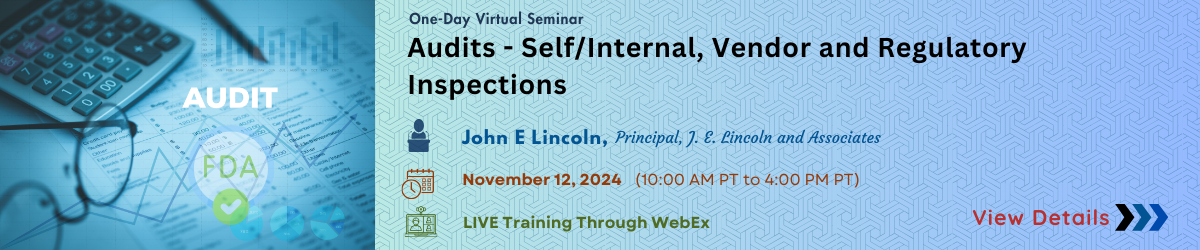

To prepare for a GMP Inspection, it is important to understand how an audit works, what to do when the inspection team arrives, rules you should follow during an audit, how to manage a typical inspection, typical points of interest to the auditors. This FDA GMP inspection training will walk you through the elements you should plan for, the timing and the logistics of who should do the various components in preparation for the inspection.

Due to the extreme criticality of GMP audits and the potential consequences, many pharmaceutical manufacturers have adopted a program of internal GMP audits to find and correct areas where the firm is not in full compliance with the GMP regulations before an FDA audit occurs. The programs GMP auditor training for pharmaceutical companies and Internal GMP Audit Program - Execution and Communication will provide valuable assistance for inspection-readiness.

GMP Training Programs to help you become "Brilliant on the GMP Basics" and Never Stop Improving

2-Day In-Person Seminar by Ex-FDA Director

Quality and GMP Compliance for Virtual Companies (Pharmaceutical, Medical Device & Biologics Industries)

2-Day Workshop

Pharmaceutical Quality Management System (GMP Requirements, ICH Guidance, QbD, and USFDA/EMA Regulations)

2-Day In-Person Seminar

Exploring Data Integrity To Include FDA, WHO and EMA's Latest Guidance for Industry (2018/2019)

Webinar

Annual Current Good Manufacturing Practices (cGMP) Training

Webinar

Food cGMP's 101: Understanding critical FDA expectations for safe food manufacturing to assure a favourable audit

Webinar

CGMP controlled Raw Materials